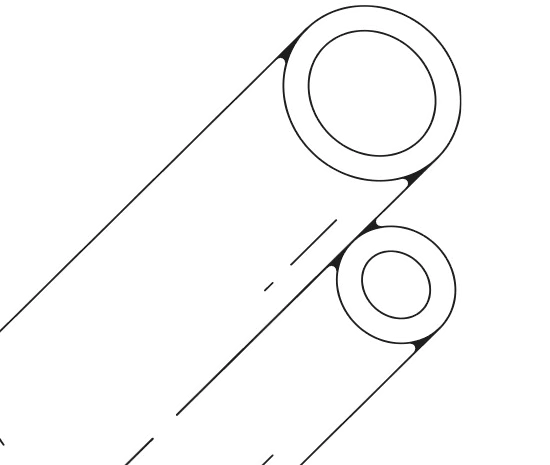

Stainless Steel Bright Bars

Bright bars have a very precise shape and structure and a shiny appearance. To achieve the various sizes, there are five main processes that bright bars may undergo – drawing, peeling, grinding, polishing and cold rolling.

Synergy ensures that its bright bars have the smoothest surfaces and the highest ductility and beam strengths. They are used in pump shafts, conveyor belts, valves and nuts and bolts among others.

Equipment

- 2 pre-straightening units

- 2 combined drawing units with a speed of 55 m/min

- 2 straightening units

- 2 vertical type roll straighteners

- 2 polishing units.

Specifications

| Type | Size Range | Length | Finish | Tolerance | Supply Condition |

|---|---|---|---|---|---|

| Round | 5-16 mm | 3-6.2 m | Cold drawn | H9, H10, H11, H12, K12, K13 | 3-10 mm annealed + cold drawn + polished |

| Square | 6-12mm | Mirror Finish | H11 | 11-22 mm annealed + cold drawn polished/centreless ground | |

| Hexagon | 6-13mm | H11 | 23-110 mm annealed/hardened + tempered + smooth turned + polished/centreless ground |

Grades

| ASTM: | 201, 202, 204Cu, 301, 302, 303, 304, 304Cu,304HC, 304L, 304H, 310, 310S, 312, 314, 316,316L, 316LN, 316Ti, 316LCu, 321, 410, 420, 430,430L, 430F, 431, 17-4PH, 904L, F51, F60. |

|---|---|

| DIN/EN: | 1.4016, 1.4301, 1.4306, 1.4307, 1.4310,1.4362, 1.4370, 1.4401, 1.4404, 1.4462, 1.4541,1.4567, 1.4841, 1.4842, 1.4845, 1.4570, 1.4571,1.4578, 1.4597. |

*Specialised grades also available as per customer requirements

Packaging

Each bar is color-coded and then wrapped in HDPE cloth.