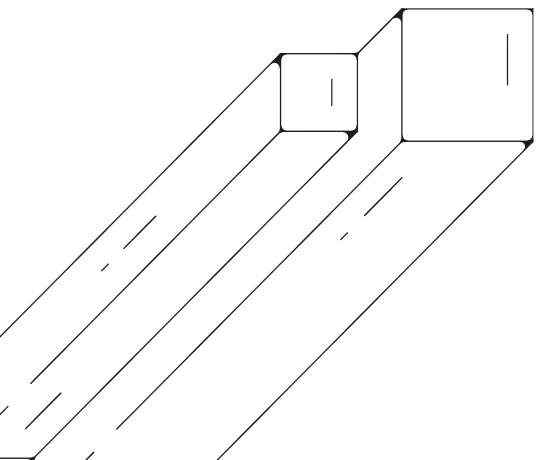

Stainless Steel Billets

Often rectangle in shape, billets are obtained from raw steel. Since raw steel cannot be used in the manufacturing process, it needs to be shaped.

Equipment

| Equipment | Capacity | |

|---|---|---|

| Radiation Detection System | ||

| Furnace | Induction Furnace | 35 MT | 20 MT |

| AOD | Converter | 35 MT | 20 MT |

| CCM | 2 Stand Continuous Casting Machine | Radius 6/11 |

| Gas Plant | Oxygen/Nitrogen Plant | 400 M3 |

| Rolling Mill | Flat and Long Products Rolling Mill | 20 Inch |

Specifications

| Type | Size Range |

|---|---|

| Billet | 100, 125, 135, 160, 170 and 200 |

| Slab | 130*170 |

Grades

| 200 series | 201/201 Super, 201 LS, 202, 204Cu |

|---|---|

| 300 series | 301, 302, 303, 303Cu, 304, 304L, 304L10Ni, 304H, 304HC, 304LSi, 307Si, 309, 309S, 310, 310S, 314, 316, 316L, 316LN, 316Ti, 316LCu, 317, 321, 321H, 409, 410, 420, 430L, 430F, 431 |

| 400 series | 409, 410, 420, 430L, 430F, 431 |

| Electrode Grades | ER304, ER304L, ER304LSi, ER307, ER307Si, ER308, ER308LSi, ER310, ER316L, ER316Lsi, ER316LSiMo, ER316LHMo, ER347, ER347Si, ER309, ER420, ER43, and other specialty grades |

| Duplex and Others | 904L, 17-4PH, F51, F60, 2304 |

*Specialised grades also available as per customer requirements